Scales - FC6200 Formula Control System

Download Brochure (pdf)

Traceability and Increased Productivity

HACCP and BTA 306 compliance for lot control is achieved by tracking the lot number of each ingredient for all scaled batches. The FC6200 lets you precisely control your formulas by prompting the user through the formula one ingredient at a time. By prompting the user through the formulas, the correct ingredients are accurately scaled every time and the ingredient target weight tolerance ensures control of your operations. Efficient scaling no longer requires an experienced production employee, as the process becomes far simpler when the user is prompted through the formula. Users scaling ingredients that are distracted by other production responsibilities can now return to the partially scaled formula assured that the scale will prompt them through the remainder of the formula without error.

HACCP and BTA 306 compliance for lot control is achieved by tracking the lot number of each ingredient for all scaled batches. The FC6200 lets you precisely control your formulas by prompting the user through the formula one ingredient at a time. By prompting the user through the formulas, the correct ingredients are accurately scaled every time and the ingredient target weight tolerance ensures control of your operations. Efficient scaling no longer requires an experienced production employee, as the process becomes far simpler when the user is prompted through the formula. Users scaling ingredients that are distracted by other production responsibilities can now return to the partially scaled formula assured that the scale will prompt them through the remainder of the formula without error.

During formula scaling, each ingredient lot number is automatically traced while ensuring the ingredients meet the desired weight tolerance. The scaled formula is saved in a digital record, far more accurate than the typical hand written records used on most plant floors today.

Ingredient scrap and bad batches are eliminated by weighing each ingredient within a set tolerance, resulting in increased consistency and reduced downtime due to bad batches from mis-scaled ingredients. Your batches will now contain the correct amount of each ingredient each time, lowering overall ingredient costs.

Easy to Use Interface

Employees quickly adapt to the FC6200’s interface. Simple operation is made possible with pushbuttons using terms familiar to production employees. The display and touch panel design have been fine-tuned as a result of observing formula scaling at major food processors. Training is quick and easy due to the prompts that the user sees through each step of the formula. The color-coded Accu-Track© display on the screen ensures accurate filling with visual feedback. An optional heavy-duty barcode  scanner guarantees that lot numbers are recorded accurately.

scanner guarantees that lot numbers are recorded accurately.

Generates HACCP & BTA 306 Compliant Reports

Completed Formula Report summarizes data for each formula run on the FC6200 Forrmula Control Scale including:

- Batch ID and name

- Batch size as a percentage of total formula weight

- Time and date of formula start and complete

- Actual scaled weight

|

- Formula target weight

- Ingredient variance from target weight

- Lot ID’s for each ingredient

- Batch lot ID

|

Total by Ingredient Report summarizes the ingredient usage for all formulas including:

- Ingredient name and ID number

- Batch name that the ingredient is used in.

- Weight used for each batch and a total weight for all batches.

|

|

Total by Batch Report summarizes completed batches:

- Batch ID and name

- Total number of times the batch was run

|

|

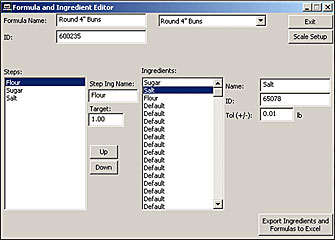

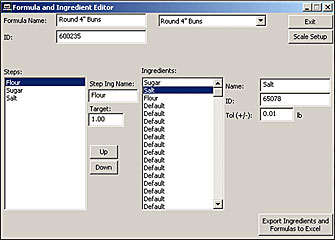

Formula Loader Software

Plant management is in control with the included Formula Loader Windows based software. Configuration of even the most complex formulas is an effortless task thanks to the simple interface layout. Enter the ingredients with tolerances and ID, then create the formulas by double clicking the ingredient names. Formula Loader will become a database of your entire library of formulas.

Plant management is in control with the included Formula Loader Windows based software. Configuration of even the most complex formulas is an effortless task thanks to the simple interface layout. Enter the ingredients with tolerances and ID, then create the formulas by double clicking the ingredient names. Formula Loader will become a database of your entire library of formulas.

Easily control which formulas are loaded into each Model FC6200 Formula Control Indicator using this custom software program. Then transfer the formulas to each FC6200 via a removeable USB thumbdrive or the optional Ethernet interface.

In one easy step, create two comprehensive Excel® spreadsheets that contain all formulas and ingredients you produce with Formula Loader. The ingredient spreadsheet records the ingredient name, ingredient ID, and the ingredient tolerances. The formula spreadsheet documents the formula name, formula ID, ingredient name, and target weights.

Specifications:

- Display

- LCD - 5.7" STN QVGA 320 x 240

- Controls

- CLEAR, ENTER, START, STOP, LOT ID, RECIPE RECALL, ZERO, and Alphanumeric Keypad

- Power

- 115 VAC, 50/60 Hz (230 VAC Optional)

- Data Output

- USB Thumbdrive or Optional Wired Ethernet

- Construction

- 304 Stainless Steel Steel (16 Gauge)

- Dimensions

- 9.25" H x 10.5" W x 5.5" D (Indicator)

- Warranty

Options:

- Meter Only Option with a Table Mount U-bracket

- IP65 Rated Heavy Duty Barcode Scanner

- Ethernet Communications

- 30" Tall Column

- Fine Ingredient Scale for accurate measurement of small ingredients (less than 0.5lb).

- Communication link to bulk ingredient batch controller.

HACCP and BTA 306 compliance for lot control is achieved by tracking the lot number of each ingredient for all scaled batches. The FC6200 lets you precisely control your formulas by prompting the user through the formula one ingredient at a time. By prompting the user through the formulas, the correct ingredients are accurately scaled every time and the ingredient target weight tolerance ensures control of your operations. Efficient scaling no longer requires an experienced production employee, as the process becomes far simpler when the user is prompted through the formula. Users scaling ingredients that are distracted by other production responsibilities can now return to the partially scaled formula assured that the scale will prompt them through the remainder of the formula without error.

HACCP and BTA 306 compliance for lot control is achieved by tracking the lot number of each ingredient for all scaled batches. The FC6200 lets you precisely control your formulas by prompting the user through the formula one ingredient at a time. By prompting the user through the formulas, the correct ingredients are accurately scaled every time and the ingredient target weight tolerance ensures control of your operations. Efficient scaling no longer requires an experienced production employee, as the process becomes far simpler when the user is prompted through the formula. Users scaling ingredients that are distracted by other production responsibilities can now return to the partially scaled formula assured that the scale will prompt them through the remainder of the formula without error. scanner guarantees that lot numbers are recorded accurately.

scanner guarantees that lot numbers are recorded accurately. Plant management is in control with the included Formula Loader Windows based software. Configuration of even the most complex formulas is an effortless task thanks to the simple interface layout. Enter the ingredients with tolerances and ID, then create the formulas by double clicking the ingredient names. Formula Loader will become a database of your entire library of formulas.

Plant management is in control with the included Formula Loader Windows based software. Configuration of even the most complex formulas is an effortless task thanks to the simple interface layout. Enter the ingredients with tolerances and ID, then create the formulas by double clicking the ingredient names. Formula Loader will become a database of your entire library of formulas.